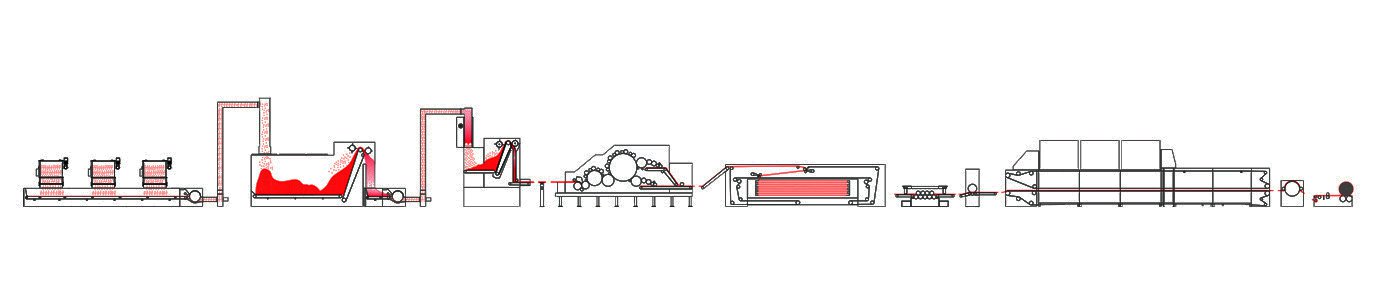

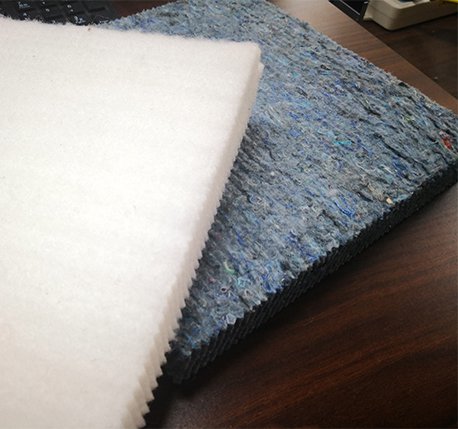

The thermal bonding process comprises, the thermally bonding of the synthetic fibers structured to be felts.

Basically, the fibers like polyester either virgin or recycled fibers, sometimes mixed with the textile waste fibers are configured together with the fibers with low melting points such as bi-component fibers or polypropylene fibers and passed through the heating chambers to thermally bond the fibers together and form a structure called waddings.

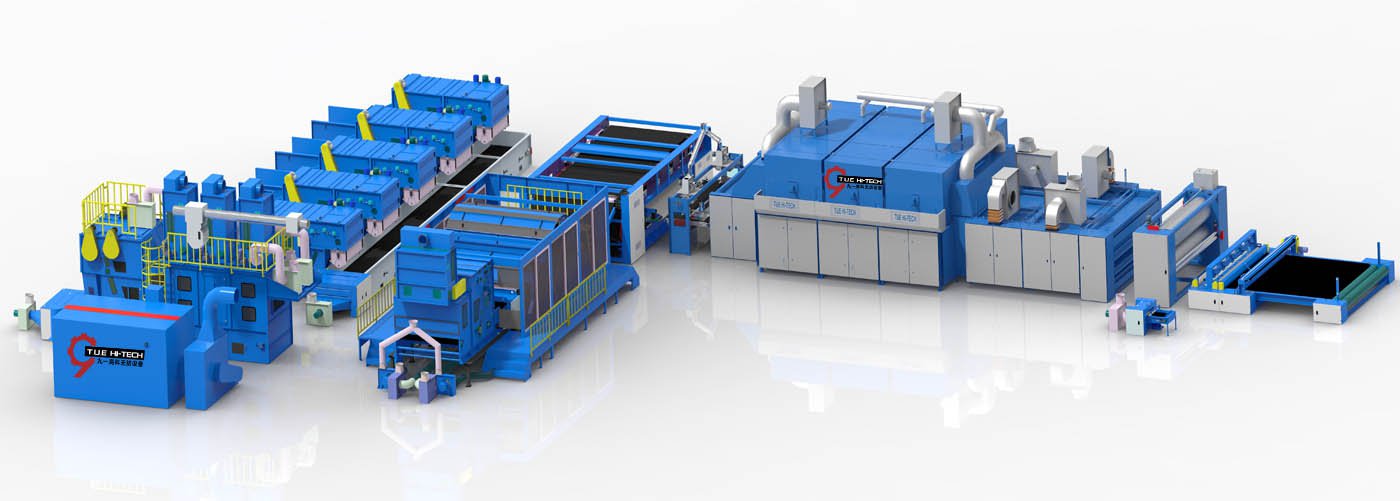

TUE HI-TECH offers a complete TURNKEY thermal bonded systems.

This process is most widely used in insulation, padding, wadding, furnitures, mattress, automotive and several other molded forms.

Besides, synthetic fibers, some natural fibers such as jute, or coconut can also be thermally bonded provided that ,they are mixed in certain proportion with the low melt fibers.

The heating is either with the gas or electric heating or some Infrared heating elements. There are several chambers in the oven along with the separate cooling units with pressing rollers depending upon the nature of intended products.